Gil’s Garage

Gil’s Garage

Gil Baumgartner

CTCI Authenticity Chairman

The Holley 4000 carburetor, standard equipment on 1955/56 Thunderbirds is a very good carburetor and probably one of the most misunderstood carburetors in existence. The average mechanic takes one look at it, has no ideal how to properly adjust or rebuild this model and usually recommends replacement. When in fact, a properly rebuilt Holley 4000 is an excellent carburetor.

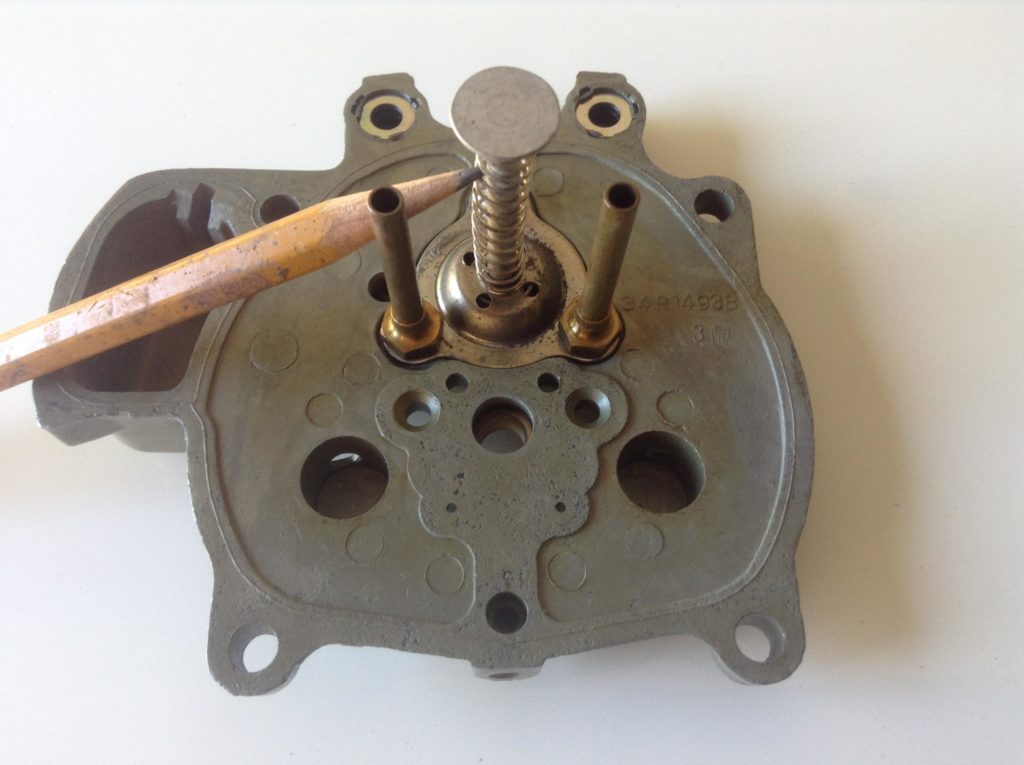

One critical item that is misunderstood and very easy to not properly install during a rebuild is the power valve system. The power valve is a brass valve that fits in the bottom of the main body fuel bowl, it is spring loaded to the closed position. (Image 1).

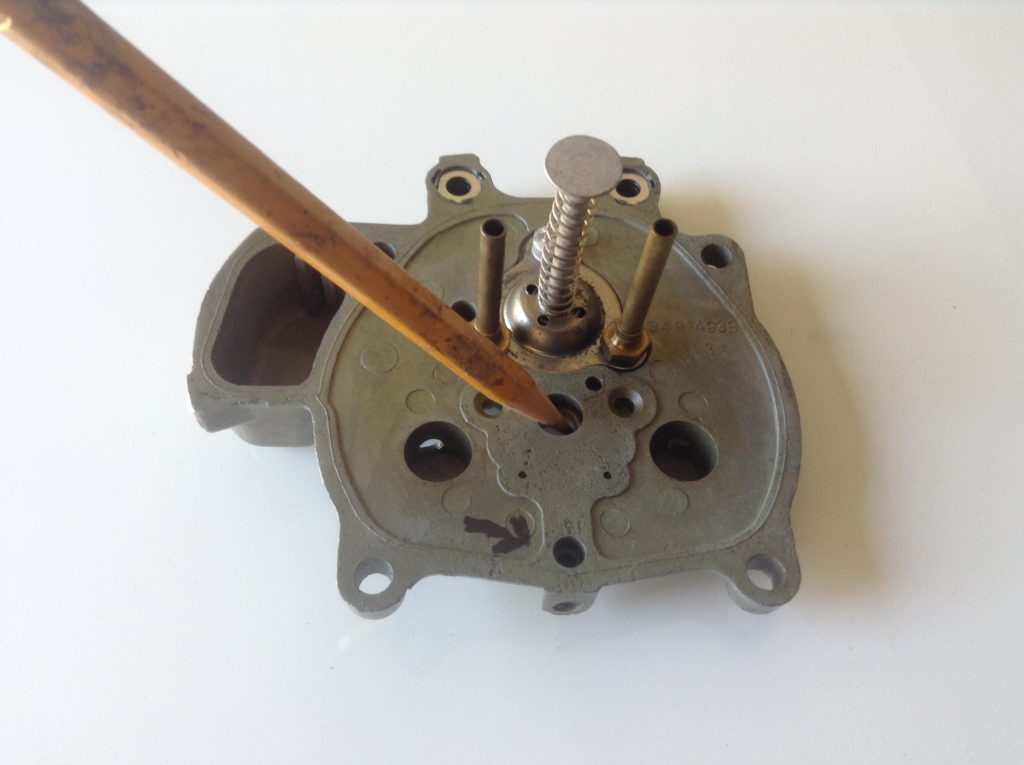

The power valve is controlled by a diaphragm and spring loaded stem. (Image 2)

The diaphragm and stem is installed inside the fuel bowl top cover. It is held in place by the secondary jets and one screw. When installing insure the rubber diaphragm is aligned with the proper holes in the stem base, two large holes and one small. Align the two large holes with the large holes in the carburetor top and secure with the brass secondary jet tubes and one small screw, all the time insure the rubber diaphragm is properly seated to the top.

Insure the diaphragm and stem is working properly by blocking both sides of the center hole in the top cover as pointed out in (Image 3) apply a vacuum to the smaller front hole in the top cover marked with an arrow in Image 3.

When vacuum is applied the stem should retract and stay retracted until vacuum is released. When vacuum is released the stem should snap to the extended position.

With the carburetor installed and the engine running at low speeds, manifold vacuum from the base of the carburetor applies vacuum to the diaphragm retracting the stem away from the power valve causing it to stay closed. When accelerating manifold pressure drops, the spring-loaded stem extends and opens the power valve. When the power valve opens venturi velocity pulls fuel from the bowl and provides the necessary fuel for acceleration.

If the diaphragm is not properly installed the stem will not retract causing poor idle conditions as well as poor acceleration and a rich running engine at low speeds.

A vacuum leak behind the choke plates – where the main body meets the throttle body – will also effect power valve operation. Go to www.ctci.org click on Car Tech, Gil’s Garage, Fuel System then Carburetor Vacuum Leak for more information.

Additional Holley 4000 rebuild information can be found in the restoration manual available from CTCI.

Gil Baumgartner